BRIEF INTRODUCTION OF THE ROTARY PACKAGING MACHINE SOLUTIONS

The automatic rotary packaging machines are also called “pre-made pouch packing machines”. It is mostly adopted to pack the pre-made flat or stand-up pouches with or without a zipper lock. Generally, it could realize the functions of pouch feeding, date printing, (zipper opening), pouch mouth opening, material filling, pouch mouth cleaning, heat-sealing, cold-sealing, and finished pouch output. Additional functions like the middle hopper system, nitrogen gas filling system, and euro hole punching system could be customized according to the users’ production requirements. Through connecting with different kinds of elevating and weighing systems, the doy bag packaging machines could be applied in different kinds of markets with stable running performance.

TYPICAL ROTARY PACKING MACHINE FEATURES

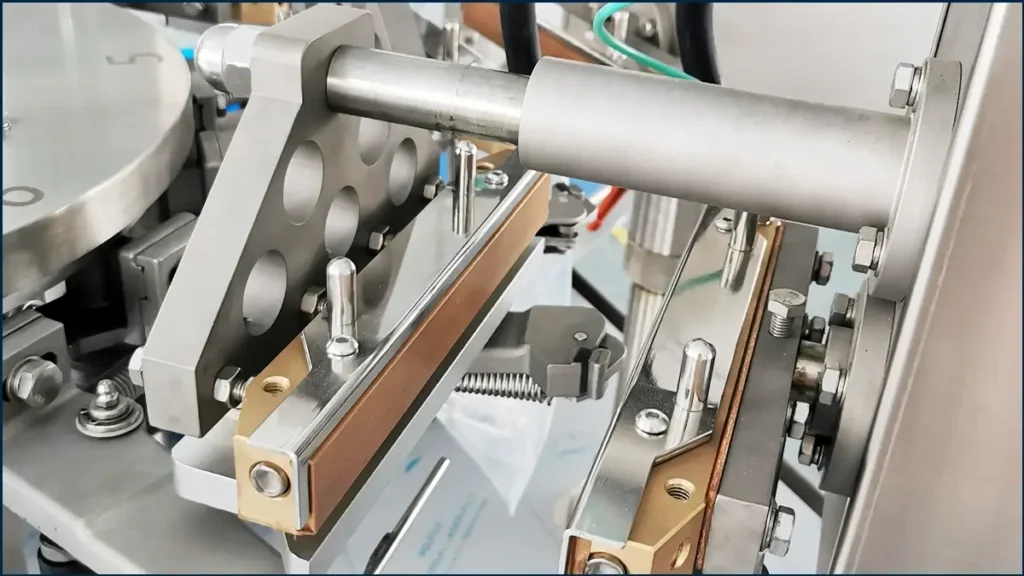

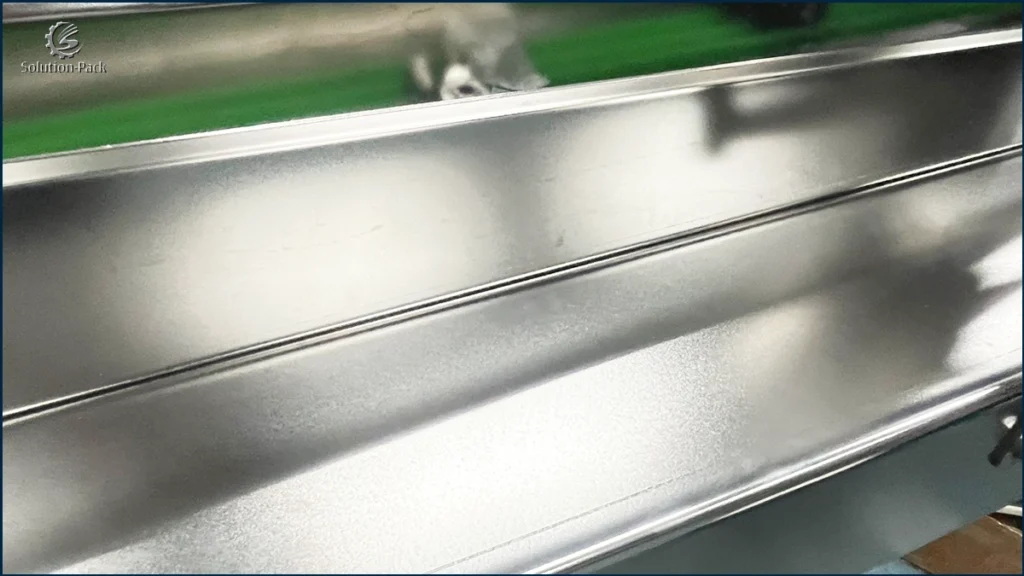

Intelligent Design

The pre-made pouch packing machine unit adopts a compact structure design pattern to save installation space for the users. The whole machine frame and the material contacting parts all adopt the food-level stainless steel to meet the food production sanitary requirement. The surface of the machine is fully polished to ensure the best appearance and cleaning convenience. The safety door system uses a transparent Lexan board which allows the user to check the mechanical movements inside the machine easily.

Advanced Configuration

As one of the professional doy pouch rotary packing machine manufacturers, Solution-Pack offers high-standard configuration for the users with a pleasant user experience. We adopt the smart Siemens PLC control with a 10-inch colorful HMI interface for convenient operation. The other related pneumatic and electrical parts also adopt AirTac, SMC, Schneider, or equal brands to facilitate the user to source the spare parts easily from the local market. Meanwhile, the user could also choose to purchase them from us directly.

Customized Features

The zipper pouch packing machine could connect with different kinds of elevating and weighing systems to pack the target products and pouches. The pouch width “fast-to adjust” function is equipped and the users only need to press the “Gripper Setting” button on the HMI to set the target pouch width when they need to change the production recipe. The middle hopper system could be assembled to improve the filling speed, and the nitrogen gas filling function could be installed to extend the shelf-life of the final products.

GUIDANCE ON SELECTING THE SUITABLE PRE-MADE POUCH PACKING MACHINE MODELS

When we judge which doy bag packaging machine is suitable for the users’ production, the exact packaging materials shall be put in the first position. The liquid products shall use the liquid elevating and dosing filling pump system, the granule products shall use the Z-type bucket elevator and the multi-head weighing filling system or the linear head weighing filling system, and the powder material needs to use the screw elevator with the auger dosing filling system. Different kinds of materials have various features, and we need to study the material features first before moving forward to set down the final solution design. Mutual communication on the project details is required to ensure the most suitable and applicable equipment for the users.

The second point that influences the machine model chosen is the pouch width. Each model machine has a certain limitation range on the pouch width due to the mechanical design of the rotary panel. The 240 series machine could allow the max. 240 mm pouch width and max. 300 mm pouch length. The 300 series machine could allow the max. 300 mm pouch width and max. 350 mm pouch length. Some users may have different pouch widths and lengths to run on the same machine unit, so we need to check if all the pouch sizes can fit in one machine model to save the cost for the users. We warmly welcome friends from all over the world to communicate with us with project details!

CHOOSE SOLUTION-PACK | FIND THE BEST DOY BAG PACKAGING MACHINE SOLUTION

- We are one of the leading rotary pre-made pouch packing machine manufacturers from China with a rich experience of over 12 years in integrated packaging solution design and manufacturing. All the machine models supplied by us could work for both flat or stand-up pouches with or without a ziplock. The advanced mechanical and electrical design allows the users to adjust the pouch width within 5 minutes. We aim at support the users to improve production efficiency, save labor costs, and improve the appearance of the final products for better marketing;

- We provide two types of after-sale service systems for the client under different conditions. If the user has a professional engineering team, we propose the online instructing installation service. We shall open the WeChat video online when the machine arrives at the client’s factory and then guide the user to install the machine unit and adjust all the parameters. However, if the user is for the first time to install the machine and without any knowledge of packaging machines, we shall arrange for our engineer to travel to the factory plant to make the installation and training work for the user. It depends on the user’s choice to conduct the work.